Nové Město nad Metují/Praha, February 18, 2019. The production of a memorial plaque is the work of a team of experts. The Memorial plaque dedicated to Ondrej Sobola was a rather complicated process. Only one family photograph with his portrait had survived (title image top). It was taken at the wedding of his brother Štefan Sobola and Mária Marec on October 20, 1906 in Philadelphia in the United States. Ondrej (the first on the right) was Štefan’s best man.

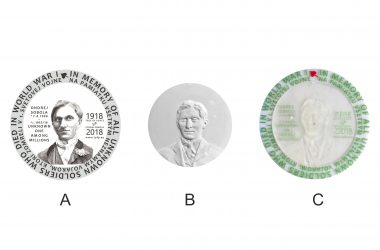

The process began with a black-and-white portrait photograph being produced by Feri Ďuriančík. Subsequently, Marek Sobola created the design of the future plaque (A). In order to create the exact model, sculptor Michal Janiga created Ondrej’s bas-relief (B). Then Pavel Fexa from Prague processed the exact model of the future plaque at a scale of 1: 1, Ø 19 cm (C). Michal Janiga cast the silicone form of the future plaque (D). The definitive plaque was made using the electroforming method (galvanoplasticity) in the Czech company Electroforming s.r.o. from Nové Město nad Metují (E).

Electroforming is a metal forming process that forms parts through electrodeposition on a model, known in the industry as a mandrel. Conductive (metallic) mandrels are passivated (chemically) to preclude ‘plating’ and thereby to allow subsequent separation of the finished electroform. Non-conductive (glass, silicon, plastic) mandrels require the deposition of a conductive layer prior to electrodeposition. Conductive layers can be deposited chemically, or using vacuum deposition techniques (e.g., gold sputtering). The outer surface of the mandrel forms the inner surface of the form. In recent years, due to its ability to replicate a mandrel surface very precisely with practically no loss of fidelity, electroforming has taken on a new importance in the fabrication of micro and nano-scale metallic devices and in producing precision injection moulds with micro- and nano-scale features for the production of non-metallic micro-moulded objects.